Set Conversion Tolerance to 0.001in or 0.0254mm. The field will be replaced by minimum acceptable value. ASAT file format, the other file format where IRONCAD is lagging behind other CAD systems is regarding STEP AP242. Vertex Spacing - This option controls the length of the edge of a facet.

A setting of 0.0000 causes this option to be ignored. Surface Tolerance - This setting controls the greatest distance between the edge of a facet and the actual geometry. A setting of 1 would mean the height of a facet is no greater than its width. Reducing the angle will increase the resolution of the STL file.Īspect Ratio - This setting controls the Height/Width ratio of the facets. The following command line options affect the quality of the STL and should be adjusted to produce an acceptable file.Īngular Tolerance - This command limits the angle between the normals of adjacent triangles. Use the AMSTLOUT command to export your STL file. Your design must be a three-dimensional solid object to output an STL file.Ĭhoose Stereolithography from Export options

#Convert ironcad to .stp software#

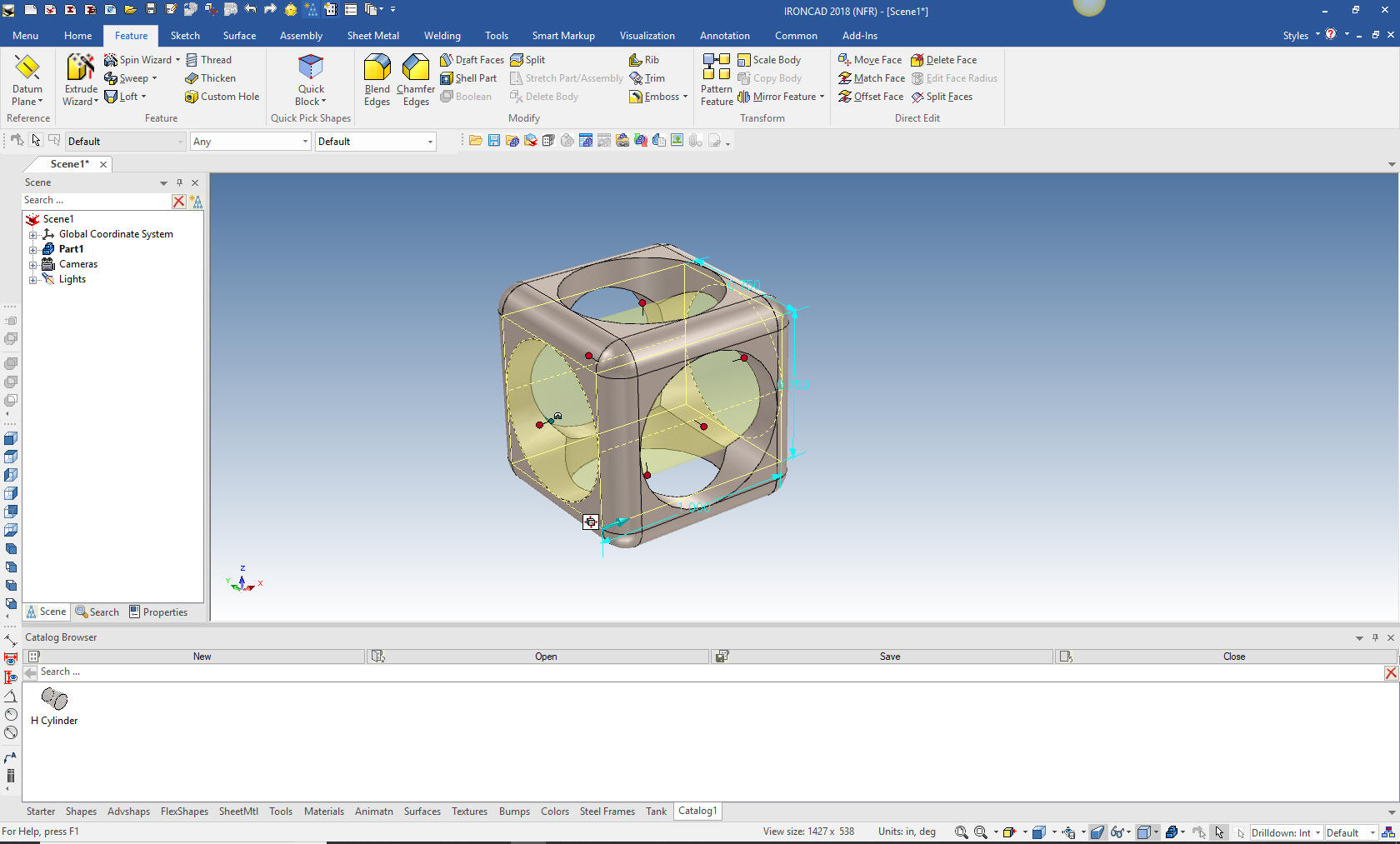

Below are general guidelines and suggestions for creating STL files depending on which design software is being used: Therefore, it is important to ensure the export options in your design software are properly tuned in order to get an accurate file without creating an enormous file. For most parts, STL files larger than 5MB are not necessary. And as a result, the more triangles, the larger the STL file. The more complex a part becomes, the more triangles are required to duplicate the part model. This STL format basically approximates the surfaces of a solid model with triangles. 3D printer prep (slicer) software typically imports an STL file, applies printer and slicer settings as specified by the user, and then exports a GCODE file which is loaded into the printer in order to create the part. Import Model in IronCAD - CAD Software Support.

#Convert ironcad to .stp how to#

STP File (What It Is and How to Open One). The defacto standard neutral file format for 3D printing is Stereolithography (.stl). Beeld STP File - How To Create, Open, View, And Convert STP Files. Creo Parametric IronCAD 3ds Max (3D Studio Max). Make sure to export as a solid and not surfaces. If you want to achieve DXF to STP conversion, you may select a proper software program the list. It is our top preference as well, but we can also use IGES (.igs) if necessary. The most common neutral file format typically used for injection mold tool design is STEP (.stp). Therefore, "neutral" files must be created and exported. The "native" design files are proprietary to the particular software maker and can't be easily read by other software packages used to design molds or print parts. Select in the dialog box the type of file you want to open, and then click OK.Properly preparing a 3D CAD file is an important step in order to ensure your design data is the best it can be before sending to an injection molder or 3D printer.ģD CAD part files are created using design software such as SolidWorks, CATIA or Autodesk. The main value of the IFC is accordance to the Building Information Modeling. It’s supported in the major software packages like Revit and AutoCAD by Autodesk, Tekla Structures by Tekla or SmartPlant3D by Intergraph. There are 2 ways to import files to IronCAD Opening a existing documentĪnd selecting the desired Files of Type, as shown below: IFC or Industrial Foundation Classes is a 3D file format, used in the Architecture Engineering Construction (AEC) segment. Add the low-cost TRANS bundle and even access native formats such as CATIA V5, Pro/E Granite, UG/NX, SolidWorks, and Inventor? Answer For a recent example, I just brought in a. Typically when we import a STEP file to use in a model, we will rebuild the model/relevant features using Intellishapes if we need to edit anything specific.

How do I import a part or a model created in file formats like IGES, CATIA V4, and STEP. Hi Craig, Unfortunately, I haven't yet found a viable method for editing imported BREP shapes other than the Move Face command as Kevin suggested.

0 kommentar(er)

0 kommentar(er)